ROTOMAC 20mm HIGH SPEED ROTARY

High-Speed Testing of Small Diameter Wire, Rod & Tube for Longitudinal Defects

- High-speed rotary features include:

- Operation at speeds up to 18,000 RPM for high production output.

- Highly sensitive non-contact testing with superior results

- New and improved, easy to set up Distance Compensation (a critical factor in testing ovate wire).

- Simple adjustment tools, with convenient dial-in diameter guide.

- Two spinning test probes that can be adjusted simultaneously for dimensional changes.

- Quick twist-on bushing holders.

- Probes that can be easily centered on the test product’s center of rotation.

- Simple probe replacement.

- Meets all applicable safety requirements.

- The 20mm Rotomac® HS Rotary delivers high-speed ECT (Eddy Current Testing) for continuous wire operations that include drawing, spring-making, parts forming, and shape and cut. The system is designed to detect longitudinal surface flaws such as seams and laps, in products measuring from 2 to 20mm (0.0787-0.7874”) in diameter

Applications Include:

- Continuous wire operations such as drawing, spring-making, and parts forming lines.

- Straight and cut operations.

- Operates in-line with straighteners, or off-line in a separate test station.

- Ferromagnetic, non-ferromagnetic, and austenitic materials.

- Tests round and ovate material.

Feature

- Operate with MultiMac® eddy current electronics.

- Systems with two, four, or six probes, each with its own detector channel.

- Accurate Distance Compensation ensures a uniform defect signal, even with off center or out of round material.

- Choose test headplates for surface or air ride configurations, depending on surface conditions, sizes, and test specifications.

- Dynamic breaking for quick stop of test probe headplate rotation.

- Rotary probes, unlike encircling test coils, are not affected by throughput speed changes such as occur in parts forming, because the probes spin continually around the test material at a fixed speed.

- Operates automatically as defects in the bar or wire create flaw signals, activate alarms, paint markers and other devices

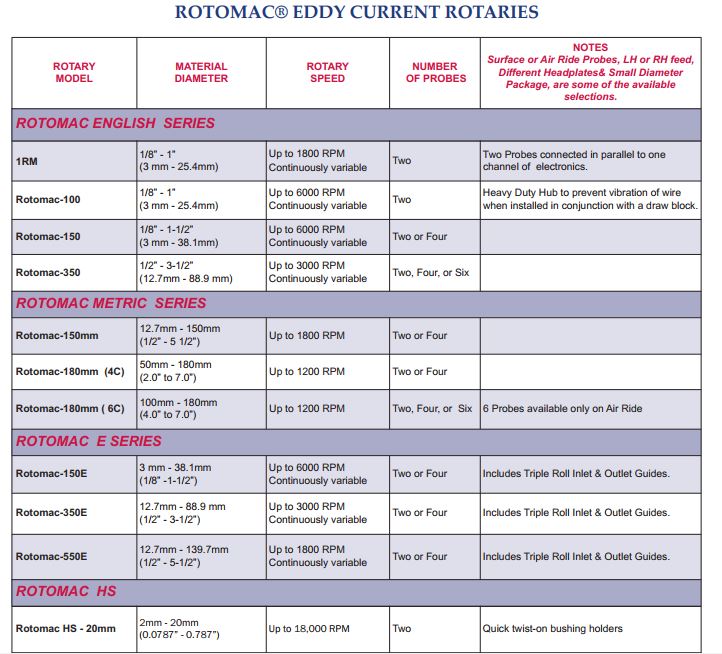

Spesification

Inquiry

Video

Tidak ada video untuk produk ini

Portable System

Portable System Integrated Online Monitoring

Integrated Online Monitoring Material Testing Machine

Material Testing Machine Vibration Sensor

Vibration Sensor Integrated Online Monitoring

Integrated Online Monitoring Portable System

Portable System Adhesive Testing

Adhesive Testing Boxes & Cartons

Boxes & Cartons Composite Films

Composite Films Films & Foils

Films & Foils Label

Label Alat Industri Sipil

Alat Industri Sipil Engine Industries

Engine Industries Food & Beverage Industries

Food & Beverage Industries Pharmacy Industries

Pharmacy Industries Paper Industries

Paper Industries Plastic Industries

Plastic Industries Power Industries

Power Industries Automotive Industries

Automotive Industries Electronic Industries

Electronic Industries Packaging Industries

Packaging Industries Manufacture Industries

Manufacture Industries Rubber Industries

Rubber Industries Oil and Gas Industries

Oil and Gas Industries Printing Testing Equipment

Printing Testing Equipment Jasa Kalibrasi Alat dan Mesin Jakarta

Jasa Kalibrasi Alat dan Mesin Jakarta NDT Portable System

NDT Portable System NDT Online Monitoring

NDT Online Monitoring Weather Station

Weather Station Data & Logger By Application

Data & Logger By Application Data & Logger By Performence

Data & Logger By Performence Data & Logger By HOBO

Data & Logger By HOBO Sensor Suhu

Sensor Suhu Sensor Jarak

Sensor Jarak Sensor Kecepatan

Sensor Kecepatan Sensor Tekanan

Sensor Tekanan Gaya Puntir

Gaya Puntir Gaya Tekan

Gaya Tekan Sensor Posisi

Sensor Posisi Sensor Optik

Sensor Optik Sensor Khusus

Sensor Khusus Sensor Warna

Sensor Warna Unit Pemrosesan Sinyal

Unit Pemrosesan Sinyal Pengukuran 2D/3D

Pengukuran 2D/3D Sensor Ketebalan

Sensor Ketebalan Sistem Inspeksi

Sistem Inspeksi